Tech Info

Welcome to Cortron’s technical support section.

Looking to get more information on Cortron designs and product characteristics? Visit our Tech Memo tab. If your hardware is determined to be faulty, damaged or malfunctioning please visit our RMA form. Looking for logistics info / support on products?

See our Maintenance / Logistics tab for cleaning instructions, connection / pinout information and spare parts listing. Be sure to have your Cortron PN.

Cortron products are designed for rugged, military, and industrial applications and environments. Click on a subject below to see related tech memos.

Cortron products are available with non-backlit keycaps (black legends) and backlit keycaps (negative image, glowing keys). Contact us for additional information on backlighting options.

Download PDF

Cortron Duratrack pointing devices have can be configured in a variety of orientations and button definitions. Click the PDF to find standard and optional configurations.

Download PDF

Cortron products are available in Table Top, Panel Mount, Rack Mount and OEM installation options. Contact us for additional information on Cortron mounting options.

Cortron products are designed to meet MIL-STD-810 and MIL-STD-901.

Cortron products are tested as individual products as well as part of system level testing.

Most Cortron products do not require custom drivers. Contact us for additional info on interfaces and connections to host systems.

Cortron products are available with a variety of industry standard and custom connectors.

Contact us for additional information on connectors and cabling.

Tech Info

RMA POLICY / GUIDELINES

Important: Please contact Cortron to obtain an RMA prior to returning products. NO products will

be accepted without an RMA.

In order to obtain an RMA, the following information is requested:

- Contact information for Cortron to follow up with in case there are additional questions

- Cortron Part Number

- Cortron Serial Number (if available)

- Failure information (Note: failure to provide failure information will incur $150 evaluation charge)

- Reported issue

- Application / installation information (ie how to replicate the failure / issue)

Returned Material Authorization (RMA) Shipping Guidelines:

- Product must be returned in ESD Packaging and suitably packed for commercial transport.

- If RMA is not sent in suitable protective packaging an additional charge may be applicable.

- All returns should be sent to:

Cortron Inc.

59 Technology Drive

Lowell, MA 01851

USA - Reference the RMA# on the outside box or shipping paperwork.

- Include a contact name, telephone #, and email address for Cortron to follow up with.

- Include a Ship To, your preferred ship method and shipping account number to send product

back to you.

Questions? Contact Cortron at 978-975-5445 or send us an email at rma@cortroninc.com

In order to return goods back to Cortron please note the following:

- Please complete this form to return material back to Cortron for repairs, upgrades, warranty, demo return or credit.

- Once this form is submitted you will receive an acknowledgment via email that we have received your request and are processing your RMA#.

- A second email will follow with your authorized RMA# (Return #) and detailed instruction including our address for returning your goods.

RMA Form

Looking for Information on a Specific Part Number?

Cortron Parts are typically formatted in an NNN-NNNN or NNN-NNNNx format.

CORTRON GENERAL KEYBOARD & TRACKBALL CLEANING RECOMMENDATIONS

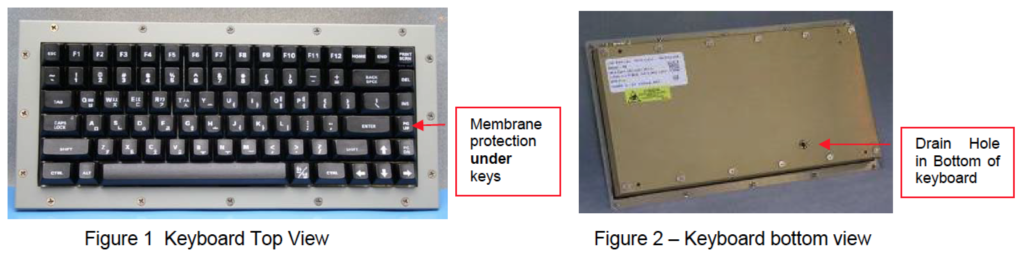

KEYBOARDS

All Cortron Rugged and most Cortron Industrial grade keyboards include an integral seal underneath the keys and typically include an integral drain for removal of rain or liquids. For cleaning of the keys and keyboard surfaces, the Cortron factory uses cloth moistened with rubbing alcohol (or isopropyl alcohol, 70-100%) for cleaning new and used keyboards. A soft bristle brush moistened with alcohol is very effective removing built up dirt or grime. Note: Customers should avoid harsh cleaning solutions and solvents such as Acetone or Ketone family of solvents. Most Cortron products will not become damaged from harsh solvents if exposure is limited to short durations – simply rinse the keyboard off thoroughly with water if exposed to such chemicals. Cortron keyboards can alternately be cleaned with most commercial non-abrasive cleaners, such as: Windex, Fantastic, or soap and water.

For large amounts of sand, dust or debris, simply turn the keyboard over and shake the debris out, or rinse under faucet as pictured below.For dried beverages or other sticky substances, a warm/hot water rinse under a faucet will help dissolve dried residual spill materials. This cleaning approach will also help dissolve food or other substances from key cavity. When performing faucet cleaning, be sure to avoid connectors on bottom/side enclosure openings for drainage, optional switches, and extra connectors when applicable. Most Cortron keyboards are very well sealed, however we manufacture a variety of different ‘grades’ of products, so each user is suggested to use their best judgment as to where water / cleaning solutions should be sprayed. The best approach for sink cleaning is to have the keyboard at an angle with the spacebar at the lowest point, washing in a downward flow. After washing, dry off keyboard and be sure connectors are dry before making electrical connection. As an extra safety precaution, shake keyboard to be sure water did not penetrate assembly. If water did penetrate assembly, let unit dry out before making electrical connection.

CLEANING INSTRUCTIONS – TRACKBALLS

Ball sizes: 1⅜”, 1½”, 2” and 2½”

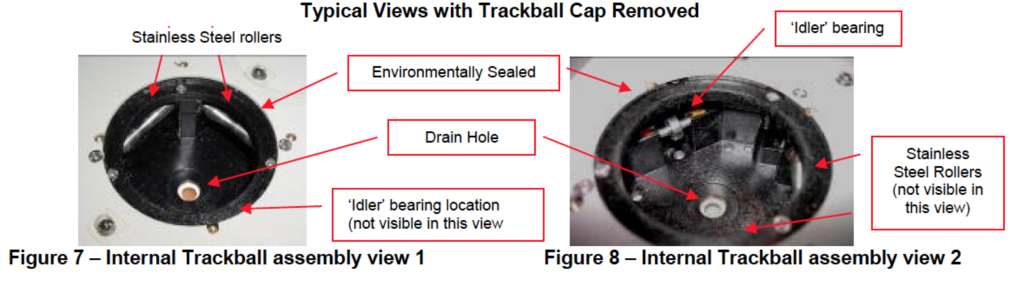

Preface: The trackball assembly components may require cleaning if ball cursor movement does not track properly. If cursor skips, does not move in certain directions, has excessive vibration or feels rough then check ball components for dirt build-up. Level of use and environmental conditions will dictate frequency of cleaning required. The ball wiper is designed to reduce the frequency of cleaning by continuously wiping the ball surface.

Note: Cortron trackballs do NOT have ESD sensitive components within ball cavity; therefore ESD handling precautions are NOT required for procedures shown here. Caution should still be taken with exposed connectors on the product.

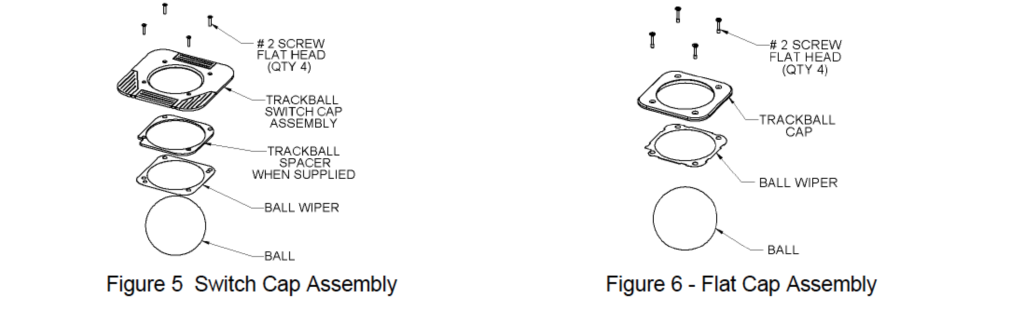

Disassembly:

∗ Unscrew 4 trackball Switch Cap or Flat Cap retaining screws (#1 Phillips).

∗ Remove trackball Switch Cap or Flat Cap, ball wiper, and ball.

∗ Clean trackball Cap, ball wiper, ball, two steel rollers, and idler bearing by rubbing with clean cloth or scraping

with appropriate tool. Isopropyl alcohol (70-100%) on a swab or cloth may help remove caked or embedded dirt or sticky substances.

ASSEMBLY INSTRUCTIONS:

* Replace ball.

* Replace ball wiper with contour of seal matching contour of ball.

* Position trackball Cap over enclosure and align holes with threaded holes in enclosure.

Note: Switch Cap assembly has (4) brass inserts that are used for screw bushing and alignment improvements.

These inserts are located on underside of Switch Cap assembly out of normal view when mounted. Be sure that

all (4) brass inserts are in the Switch Cap (these brass inserts are pressed in place for ease in transport and

handling). The Flat Cap does not have these inserts.

* Secure with 4 screws. Tighten to ‘finger tight’ (approximate torque range of 8-10 inch ounces). Do not overtighten.

If you have any questions or need additional assistance please do not hesitate to contact Cortron.